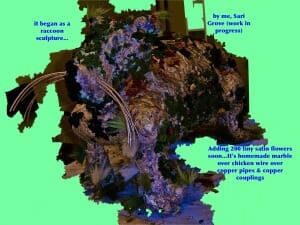

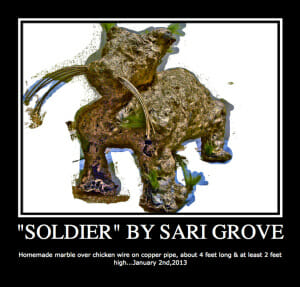

Process Photos of making the homemade marble sculpture…This was a breakthrough try for me…I used plumber’s pipes & coupling pipes to couple the pipe into a hard solid armature, it is awkward but it was still a leap forward in no-weld armatures…Later, I developed the more esoteric bendable rod design…But I had to get to here in order to get to there…(See the Daffodil for the newer ideas in no-weld armatures…)

Note:The FINISHED sculpture is covered in (not real ones)flowers…I cannot find the right picture…Messy artist syndrome…

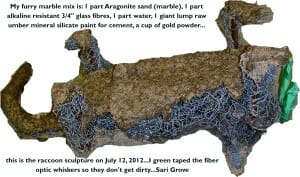

the recipe for Sari’s homemade marble(her personal invention):

“Circa 1850” powdered waterproof marine glue (resin)…1 part

Aragonite Sand (marble) 2 parts

3/4 inch alkaline resistant glass fibres 1 part

water 1 part

optional: gold powder, or mineral silicate paint (for cement)…to taste

(Truth is, it was an all brown raccoon with a very long & big nose, I think it was a different species than the grey & black & white bandit ones we see usually in Toronto…)

whiskers are of fibre optic fibre

taped to keep them clean while working…the aluminum screen mesh keeps them more separate from each other…

12/13

This No-Weld armature was made by cutting pieces of copper pipe, then using copper couplings to join them together…Then I ran wire through the whole thing to make sure it held together well…This was all wrapped in a large amount of chicken wire…It is a very stable form…My newer armatures are built using threaded steel rods bolted together using copper strapping as attachment device…The newer design allows for more curves, since the copper pipe design, well, it is hard to bend pipe easily…A ferrocement teacher named Nick Nickolson inspired my newer curvier design for a no-weld armature…He was welding, but his lines are very elegant & slim, which led me to ponder how I could make concrete more elegant & less boxy…Which forced me to think harder about the how part…

A question about making marble from India

“But Sari, it doesn’t look like a raccoon…”Well, the raccoon died, it had been hit by a car…The jaw bone protruded…I don’t work from photographs…I didn’t have a model anymore to work from…(Though a long nosed baby raccoon did some later modelling work for me)…Austin, a Portuguese Water Dog helped me fill in some of the blanks…I am an abstract artist, & that is how stories by me get told…

- A question about making marble…

Hi…We live in Canada, which is very cold for 6 months of the year & wet because we are in Toronto near to lake Ontario…So my recipes for marble & concrete were designed by me for this particular climate…Also, based on what kind of supplies were readily available… Each artisan has their own recipe, that they have devised themselves for their own needs & tastes… - You can’t really just borrow someone else`s because it won`t suit you… The important thing is to try to understand the essence of what you are trying to do, then devise your own way of doing it…To suit your budget, climate, & abilities…It took me a year to understand concrete-by reading books online & asking other artisans, by being a member of forums like the artconcrete Google group forum…There is no easy fix nor answer… But it can be very rewarding…

- Once I understood cement, which is the basis for concrete, I was able to understand marble & porcelain…Very very basically, for cement sculpture, we needed 4 parts white cement to two parts aggregate…That aggregate was in 4 parts itself…Aggregate: white silicon sand for strength, perlite for lightness, calcium carbonate sand for malleability (also called marble sand or aragonite sand), & most importantly alkaline resistant glass fibres in 1/2 inch or 3/4 inch length at least…Plus 1 part water…To that water we added \”Milk\” also called latex adhesive (liquid) which makes it all more waterproof…Colour needs to be special cement paint, not regular paint…It comes in a powder & needs to be added into the mix, not on…You can also mix in cement paint in small amounts, the liquid kind…

- But only special for cement paint…Ok so that is concrete, for concrete sculpture…It must lie on top of an armature…I explain a very ingenious way of making a steel armature without welding on my site…

- Look for No-Weld armature how to…On top of the armature, you need a mesh or chicken wire for the material to grab to…I am not doing casting here…These are one at a time…Casting molds is different…The mix is more liquidy…Once you understand concrete, you can start to experiment with marble mixes…My concrete mix incorporates marble as Aragonite sand (marble sand or calcium carbonate sand)…Using cement in your marble mix can be very strong…Stronger than all marble…

- So you may want to change your ideas about what you want to do…A concrete marble mixed recipe may be much better for doing what you are trying to do…For all marble, essentially you need:Some sort of marble sand, Aragonite sand, calcium carbonate sand…Find out what is easily available in your area…Anything in that category…(I used aragonite sand because I can buy it from pet stores easily-it is a kind of marble)…Each kind of marble has different hardnesses…I found I needed the alkaline resistant glass fibres…

- I used 3/4 inch length & bought from a specialized cement supplier…These provide much needed strength…Very important! You may think it is expensive, but the work will last…Use them!”Milk”-latex adhesive liquid…This is a gluey liquid…25% of it instead of water, then add your water…water is minimal or your mix falls apart…

- Err on less with water…Add more milk to water if you need it to be more waterproof…Milk will make it more pliable, less cracking, but can make it softer…Glue…

- Yes, this was your question…You need some sort of glue…I tried many different types of glues & they all work…I settled on Circa 1850 powdered marine glue in a can because it was very strong & waterprooof…

- You need to always wear a respirator when working with glue…Not a dust mask, a respirator…With the two canisters at each side…Glue will give you a headache…

- It is what makes the process uncomfortable…because of the need for some sort of glue, it makes the concrete mix more attractive…because when you use cement it acts as your glue…

- It is still dangerous, but in some ways less annoying than straight glue…I used Eco-House\`s cement sealers…They made me a special mix that is graffiti resistant & no VOCs… eco-house.com (they can maybe advise you about eco-friendly cement sealers in India?)

- You can put gold powder into the eco-sealer & brush that into the wet material to give a gold finish…Or any colour…You need to find out what is available in your country, in your town, easily…

- You need to experiment with mixes to see what you like…\n\nFind out what glues (you used the word “gels”, they often call glue “resin”), are available in your town…You will have to use what is available locally to you…

- Use ECO-FRIENDLY materials if you possibly can…

- This will save you many many headaches later…You should know that making multiples is not a money making business because these days so many companies are doing this already for very cheap…If the work is truly great & original you may have a chance…But this is a labour of love…

- It is complicated…It must be done by a skilled person…

- Do not go into this as a money maker…You`d be better off studying accounting…

- It is difficult…Understand also that when you cook marble it becomes porcelain…But in India, in the hot sun, your marble may do that without needing an oven…This makes it harder but in some ways more fragile, like a dish…Sanding the marble also makes it shinier…This is a bonus thing to do…

- The glue part is the problem…Sorry I don`t know the names of what glues are in India…Look for the word “resin” when you search companies in your area…Then try out small batches…Make a small mix & see how it survives…You will have to invent something just for your little company…Part of what you are selling is your own genius…You can\`t just copy another company`s genius & expect to make a profit…I hope this helps!Sari Grove(Sari created some of her infographics on Infogr.am)(the text above is from one of those infographics…)